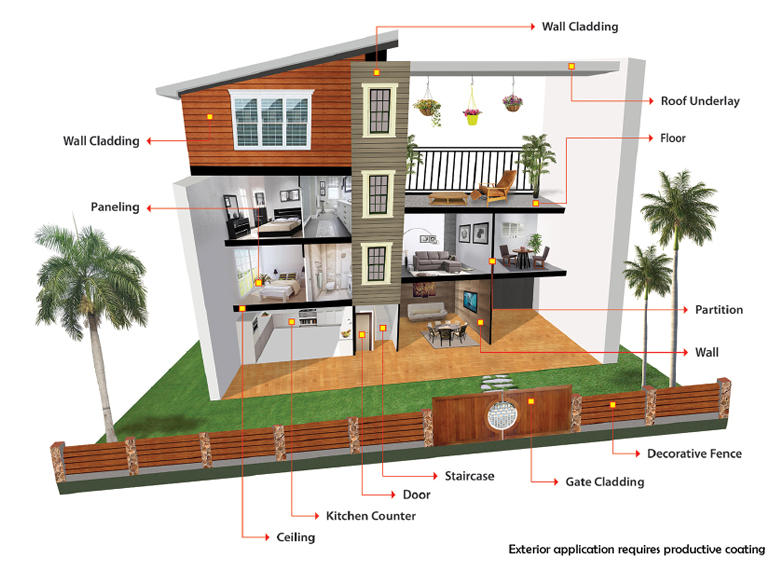

PROPERTIES

-

FIRE RESISTANCE

COMBUSTIBILITY

Hicem Boards are non-combustible as per

BS: 476: Part-4-1970. -

IGNITABILITY

Hicem Boards are not ignitable and conform to

BS: 476: Part-5-1979. -

FIRE PROPAGATION INDEX

Fire Propagation Index I = 0.7,which is the best in Class as per

BS: 476:Part-6-1989. -

SURFACE SPREAD OF FLAME

Hicem Boards conform to

BS: 476: Part-7-1997

Class I as perindicating that it Panerai Luminor Base Replica does not allow spread of flame

-

WATER RESISTANCE

Hicem Boards are water resistant and are not affected even after soaking in water for 24 hours

-

NO MOULD GROWTH

Hicem Boards are made from natural minerals which are inorganic in nature and hence free from mould growth.

-

TERMITE RESISTANCE

Hicem Boards are made mostly of inorganic minerals and are termite resistant.

-

THERMAL INSULATION

Hicem Boards have "K" value of 0.18 W/m-K, and hence contribute enormously to energy saving

-

100% Asbestos Free

Hicem Boards are manufactured using cement, cellulose fibres with special additives and do not contain Asbestos.

DIMENSIONAL STABILITY

Hicem Boards are cured under HPSC (High Pressure Steam Curing) which causes an irreversible matrix change providing high dimensional and chemical stability accompanied by low alkalinity.

SEAMLESS FINISH

Hicem Boards can provide seamless finishes when installed with most forms of paints, wall papers and laminates.

APPEARANCE

Hicem Boards have an off-white, superior texture making it suitable for all kinds of finishes.